![]()

MXRR TITANIUM GRADE 5

COMPONENTS

MXRR offers

different components realized in premium Titanium Grade 5.

Titanium is a metallic non magnetic element which is present in nature as Oxide

(TiO2).

Pure titanium (sponge) is obtained by:

-

TiO2

chlorination with thermochemical reduction of TiCl4 (Kroll and Hunter process).

-

TiO2

chlorination with electrolytic reduction of TiCl4 into mineral salts.

The obtained processed titanium sponge can be remelten in blooms, ingots

and billets.

By rolling, drawing and extrusion you obtain the main semimanufactures

available on the market: bars, tapes, wires, sheets and pipes.

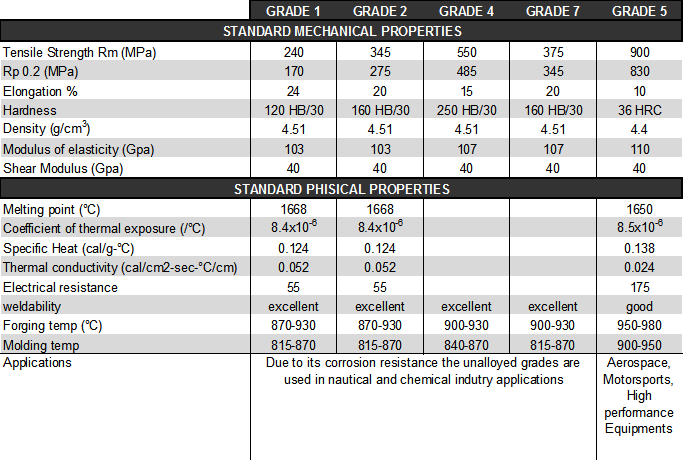

Main chemical-physical characteristics of titanium alloys:

-

High corrosion resistance

-

Good mechanical resistance

-

Lighteness (4.4 kg/dm3)

-

Low thermal expansion coefficient

-

Low electric conductivity

-

High elasticity

-

Non magnetic element

These extraordinary characteristics have increased the use of titanium for

many applications.

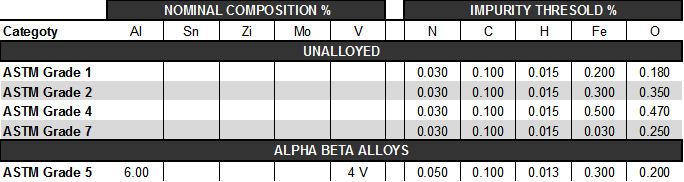

Titanium is available on the market as pure titanium or as alloy. Pure

titanium has a crystal-line structure of alpha type (compact hexagonal): it is

graded from gr. 1 to gr. 4 and presents an increasing mechanical resistance.

Titanium alloys have a crystalline structure of aplha+beta type

(body-centered cubic), with addition of stabilizing agents, such as Aluminium

and Vandium. Those alloys are the most commonly used, since they give best

ration between weight and mechanical resistance.

The actually most commonly used alloy is Ti6Al4V (Grade 5 titanium), largeley employed in screws and mechnaical components manudacturing.

Known as

the “workhorse” of the titanium alloys, Ti 6Al-4V (Grade 5 titanium), is the

most commonly used of all titanium alloys. It accounts for 50 percent of total

titanium usage the world over.

Its

usability lies in its many benefits. Ti 6Al-4V may be heat treated to increase

its strength. It can be used in welded construction at service temperatures of

up to 600° F. This alloy offers its high strength at a light weight, useful

formability and high corrosion resistance.

Ti 6AI-4V

usability makes it the best alloy for use in several industries, like the

aerospace, medical, high performance components.

Main

applications:

-

Aircraft

turbines

-

Engine

components

-

Aircraft

structural components

-

Aerospace

fasteners

-

High-performance

automatic parts

-

Marine

applications

-

Sport

equipments

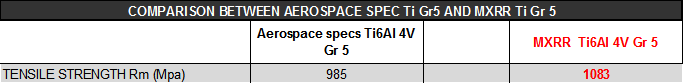

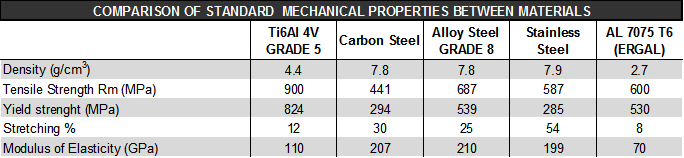

The table

below shows as Ti 6Al-4V hase a strength that is very comparable to grade 8

steel that are used in high strength

applications. Furthermore, based on the density figure above grade 5 titanium

is 45% lighter than steel components.

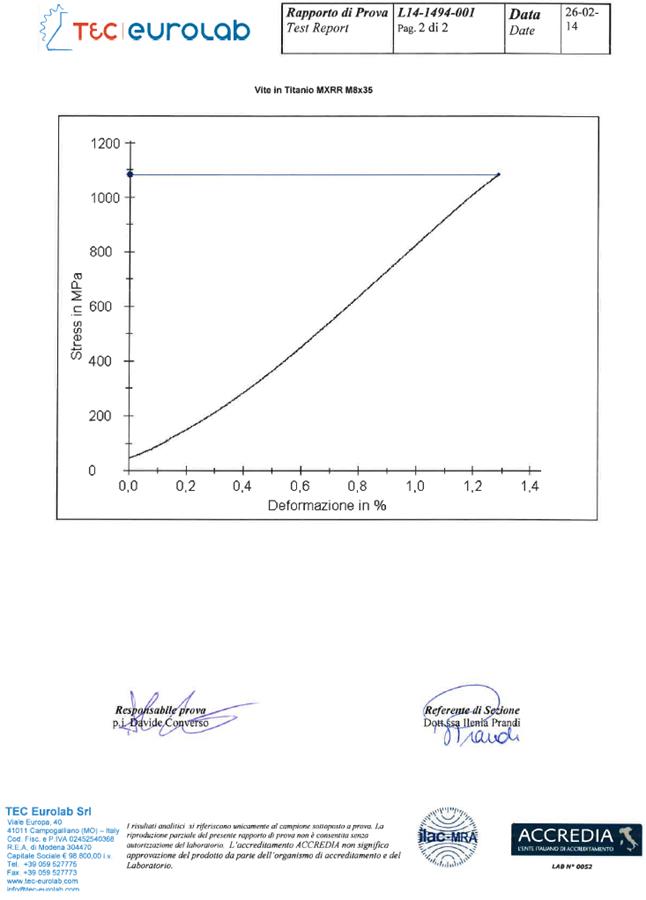

All of MXRR

Titanium components are made with PREMIUM GRADE 5 Titanium Alloy with

outstanding mechanical performance. The result below shows the result of a

CERTIFIED LAB TEST performed on a set of MXRR Titanium bolt.

MXRR

Grade 5 Titanium with Ultimate Tensile strength up to 1083 MPa EXCEEDS

top

quality aerospace certified specs (UTS Avg 985 MPa)